What is Bamboo Fabric?

Bamboo fabrics are usually produced from the fibers of the bamboo plants. Bamboo has apparently been in use for centuries to manufacture fairly a multiple array of products that spread from clothes and furniture to food items. On the one hand, bamboo fabrics was not completely adopted until relatively lately, but now it is increasingly replacing traditional fabrics in garment and fiber industry.

There are two main methods to produce bamboo fabric, namely the waste pulping process and the retting process. Most preferred method includes a procedure called as viscose. Viscose is a type of mashed rayon which is a half-synthetic fiber which is made from cellulose. Cellulose is of plant cell wall constituent and can be extracted from bamboo being using chemical procedure. After that, the whole cellulose is extracted, and then that is spun into the fiber that can be used to make fabric.

How Bamboo Fabric is Made?

Fabrics derived from bamboo enjoy the benefits of being environmentally friendly besides being relatively more silky feel. It has several stages in the preparation of fabric from bamboo, all in an attempt to make the fabric as sustainable as possible.

- Harvesting Bamboo: Starting from the extraction of bamboo plants, this is how bamboo textiles come into the market. Bamboo is perhaps one of the most renewable material because it grows very fast it is devoid of pesticides and fertilizers. This is why bamboo material becomes the suitable fabric to be incorporated into the fashion industry.

- Breaking Down the Bamboo: After that the bamboo stalks are processed and chopped into small pieces nad left in a solution to soften the fibres. This process aids in the modification of the bamboo fabric making its material easier to handle and transform into fabric.

- Extracting Bamboo Fiber: The softened bamboo is then compressed to extract the bamboo fibers The softened bamboo is then mechanically crushed out for the fibers. Such fibers are then washed and spun to make the yarn. This step is very important when producing bamboo organic fabric since the fibers need to remain natural.

- Spinning and Weaving: The fiber of bamboo is first of all spun into yarn and the yarn turns into fabric. This process may be done in a traditional or new method of weaving which makes it possible to obtain a number of bamboo textile products with varying surface characteristics and treatment.

- Dyeing and Finishing: Last of all, the bamboo fabric is then coloured and ready for the market. Organic dyes are especially employed to ensure that the bamboo material has low impact on the environment. The end product is very soft, porous and suitable for various use such as garments and home products.

Symphony Fabrics: Experience the Difference

By selecting Symphony Fabrics, you don’t only get a unique quality material but also help the planet in making an ecological decision. Our bamboo is:

- Incredibly soft and breathable: Ideal for sensitive skin and all-season warmth.

- Naturally antibacterial and odor-resistant: It keeps you feeling clean and confident.

- Moisture-wicking and temperature regulating: Keeps warm in winter and cold during summer.

- Biodegradable and compostable: Minimizes your environmental footprint.

What are the benefits of Bamboo Fabric?

bamboo fabric advantages :

Bamboo fabric has been widely accepted for its advantages, and its usage can be fixated on the fact that the fabric can be pretty beneficial in as many industries as possible.

Here’s a breakdown of its advantages:

Soft and Luxurious: Bamboo fabric is incredibly smooth; it is usually referred to as being silky against the skin making it comfortable to wear.

Breathable and Thermoregulating: The fabric made from bamboo also enjoys the prestige coming with excellent venting capabilities due to microscopic holes in the fabric fiber. They are moisture wicking, this aids in body heat transfer and insulations, ensuring one feels cold during cold weather and conversely for hot weather.

Antibacterial and Odor-Resistant: It is well known that bamboo is naturally bacteriostatic and fungistatic – in other words, it is hostile to bacteria which can cause odors. This makes bamboo fabric suitable for use in active wear and any other clothing article to be worn for several hours at a go.

Hypoallergenic: Bamboo fabric is also non-allergic to the skin and a plus for any person with sensitive skin. It reduces the tendency of allergic reactions prevalent with other natural fibers used such as wool.

Eco-Friendly and Sustainable: Bamboo is one of the fastest growing plant which does not need many water and pesticides to be produced. It has warmly favorable effect on the environment of the planet during the process of its production.

Durable and Long-Lasting: Generally, bamboo fabric is very durable, and does not lose its feel or fading even after washing it repeatedly.

UV Protection: The fabric helps promote natural UV protection of the skin to avoid exposure to dangerous ultraviolet rays of the sun.

How Bamboo Fabric is Used?

Bamboo fabric is the ultimate material, as it goes to show how many products contain it of the sheer number. Here are some of the most common uses:Here are some of the most common uses:

- Clothing: Let the jam session begin! Cloth made of bamboo is luxuriously soft and thus can become suitable for a variety of clothes like shirts, socks or underwear. Even it can occasionally cover the clothes people are wearing.

- Bedding: Bamboo fabrics sheets, pillowcases, and blankets are commonly being used on-premises owing to their soft and absorbent quality.

- Towels: Bamboo towels are widely used due to being versatile and at the same time very absorbent and velvety.

- Home Goods: Seek for bamboo in goods such as carpets, curtains, bedsheets as well as the head coverings.

- Medical and Sanitary Products: Due to bamboo’s inherent antibacterial undertones, it can be employed for usage areas like bandages, wraps, and cleaning supplies.

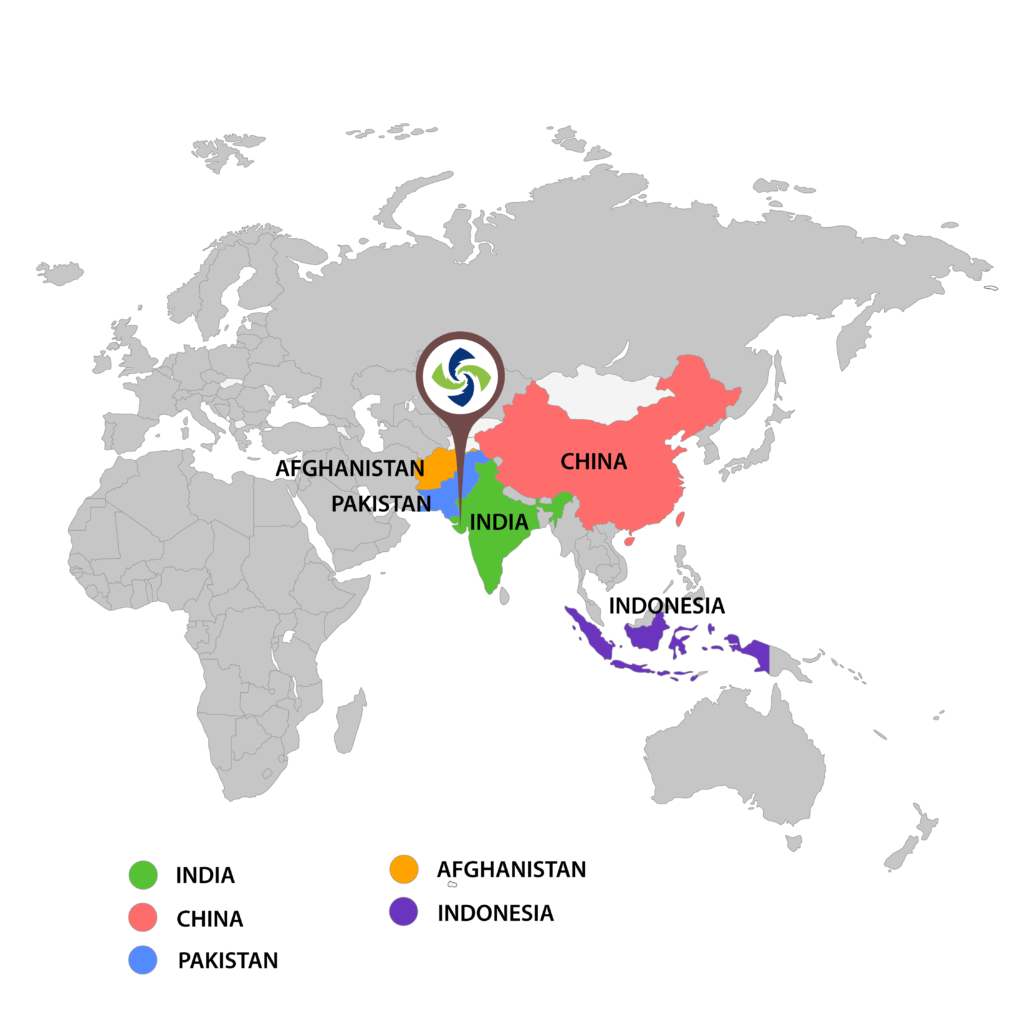

Where is Bamboo Fabric Produced?

How Much Does Bamboo Fabric Cost?

The cost of bamboo fabric can vary depending on several factors, including:

- Blend or 100% bamboo: Fabric solely originated from bamboo typically comes at a premium relative to blended counterparts either with cotton or other materials.

- Weave and weight: The most profound design weave like plain weave would be the lowest price compared to the more complex weave like French terry. And for you to have a heavier weight, you will need to pay more than the lighter weight.

- Organic vs. conventional: The OECD report, “The Role of Organic Agriculture in Addressing Climate Change,” has borne witness to how an increasing adoption of organic farming practices globally reduces greenhouse emissions significantly and therefore, contributes substantially to the mitigation of climate change.

- Dyeing and finishing: Dyed fabrics or printed fabrics would generally be the priciest ones and they may be more than the fabric being natural ivory colored.

Here’s a general range for bamboo fabrics cost per meter:

- ₹200 – ₹500 (approx.) for plain weave bamboo

- Up to ₹1400 (approx.) for specialty weaves like bamboo French terry

How Does Bamboo Fabric Impact The Environment?

Bamboo fab has the potential to be a more sustainable choice than some other fabrics, but it depends on the manufacturing process. Look for brands that use mechanical or enzymatic methods to process bamboo, which are less reliant on harsh chemicals. Additionally, choosing bamboo clothing from companies committed to sustainable practices can help reduce the environmental impact.